As darker beers provide the overarching focus in Beer & Brewer‘s current Winter edition, our resident home brew guru John Palmer guides you through brewing some of his all-time favourite styles.

I like a malty beer – that rich bready, toasty bread crust, just-out-of-the-oven flavour with a dry finish that invites another drink. People often ask me what my favourite beer is, and I reply that it’s either a classic West Coast IPA or a Munich dunkel. But not only a Munich dunkel, as my first beer of the day at any new tasting room or pub will be a dark amber lager or ale with a predominately malty balance and dry finish. Sometimes the results are disappointing, but if it is good, it’s a sure sign that the brewer knows what they are doing, and the rest of the offerings will be up to snuff as well.

All brown ale and lager styles share a common malty base – often utilising Munich base malt or other base malts and specialty grains, to build up that rich, just-out-of-the-oven character. Common specialty malts include the toasted Amber malts like Biscuit (TM), Victory (TM), or CaraAmber (TM), as well as the usual caramel malts and chocolate malt. I often use 1-2% of Roast Barley or debittered black malt to add more colour to my brown ales, as well as a certain dryness to the finish. The restrained and judicious use of specialty malts is required because these are brown beers, not ambers, porters or stouts. I don’t recommend more than 15% of your grain bill to be specialty malts, and of that, I recommend that your roast malts be no more than 5%. A mathematically easy recipe could be 8.5 lbs (3.85kg) of base malt, and a half pound (226gm) each of Crystal 80L, Biscuit, and Chocolate malts. But of course, there are many ways to skin that cat.

Brown beer styles

There are several brown beer styles to choose from and it may help to describe a couple of them. Munich dunkel is a malty bready style, without the toasty character of English mild, brown, or porter. Dunkel can have a sweet or dry finish, depending on the amounts or ratio of caramel and roast malts. A 1:1 ratio will be dry, although even a 3:1 ratio of caramel to roast is not going to be excessively sweet, assuming that your specialty malts are not exceeding that 10 or 15% threshold. A low caramel dunkel (ie. low residual sweetness) would be similar to a schwarzbier. English mild and brown ales typically include the toasted Amber malt component while maintaining a relatively dry finish. American brown ales crank up the brown-ness by taking the total specialty malts up to 20%, but still maintaining balance of the essential dry malty character. Increasing the sweetness or roastiness of an American brown takes it into American amber or porter territory, respectively.

Hops & yeast

This brings us to the question of hops and yeast choice. I would say that brown lager styles are generally more malt forward than brown ale styles, which is to say that brown ales generally have more hop character than the lagers. The balance of these styles is very important to good drinkability. The gravity units to bitterness units (OG to IBU) ratio should be 2:1. For example, a 1.050 OG beer should contain 25-ish IBU to be correctly balanced. Here is another good rule of thumb: the more complex the grain bill, the less complex the hop character should be. Or to put it more bluntly: lager styles should only use bittering additions, while ale styles should use mainly bittering additions plus light finishing hop additions. You don’t want to muddy your lovely maltiness with hop flavour, but some hop aroma can be a nice touch. The wrong hop variety can come across as vegetal, so consider your aroma hop selections carefully. Avoid sulfury hops – those that smell dank, oniony, or garlicy. Citrus and floral hops are a better choice in my opinion.

Any brown beer recipe can be brewed with either a lager or ale yeast, and the choice is entirely up to you. I would choose whichever best suits your local conditions. Choose a yeast that best suits the particular style of brown beer you want, and be sure to pitch a sufficient amount – better too much than too little. I generally prefer using a lager strain, like 34/70, or Chico ale, or an English ale strain. These beers should not be hazy, so I don’t recommend the higher attenuating but low flocculation English strains. A healthy pitch will take care of attenuation. Speaking of attenuation, I generally use a single temperature infusion mash of 65-67°C, and will often mash out at 70°C. I use a full hour long mash because I am not in a hurry and the time passes quickly while I am cleaning my immersion chiller and fermenter. Invariably, I am looking for a hose adapter or band clamp to connect the chiller and prevent it from leaking into the wort.

This would be the formula for a standard brown beer just waiting to be tweaked:

OG: 1040 – 1.060

FG: 1.010 – 1.015

IBU: 20-30 (half of OG)

Colour: 30-60 EBC

Malts:

85% Pale Ale malt

5% Amber malt

5% Caramel 80L malt

5% Chocolate malt

Hops:

The variety is your choice but I suggest a mild citrusy or floral hop.

20-30 IBU of a bittering addition at 60 minutes.

0-5 IBU of a finishing hop, steeped after boil for 15 minutes.

Yeast:

Ale (0.75 billion cells per litre per °P), lager (1.5 billion cells per litre per °P).

John Palmer’s Dunkelbock recipe

All grain

(expected figures)

OG: 1.060

FG: 1.015

ABV: 6.0%

IBU: 30

Volume: 19 litres

Ingredients

3.2kg Vienna malt

1.6g Munich malt (10L)

430g Crystal malt (80L)

110g Roasted barley

44g Mt Hood hop pellets

Yeast: 34/70 lager (1.5 billion cells per litre per °P)

Method

1. Mash in to hit 65°C for 60 minutes.

2. Sparge and transfer to kettle.

3. Once boiling add all Mt Hood hops for a 60 minute boil.

4. Flame out and whirlpool.

5. Cool wort to 12°C and run into fermenter.

6. Oxygenate or aerate and pitch yeast and maintain 12°C during fermentation.

7. When FG stabilises, keg or bottle as usual.

Extract with specialty malts

(expected figures)

OG: 1.060

FG: 1.015

ABV: 6.0%

IBU: 30

Volume: 19 litres

Ingredients

2.4kg Vienna malt extract

1.2kg Munich malt extract

430g Crystal malt (80L)

110g Roasted barley

44g Mt Hood hop pellets

Yeast: 34/70 lager (1.5 billion cells per litre per °P)

Method

1. Heat 5 or 6 litres of water in a large pot, and mash specialty malts at 65°C for 30 minutes in a malt bag or large hop bag.

2. Remove bag from liquid and allow to drain, then bring to the boil.

3. Once boiling, add all hops for a 30 minute boil.

4. At 30 minutes, flameout and stir to create whirlpool for a few minutes.

5. Transfer pot to ice bath or cool water to cool wort, then tip into fermenter leaving behind as much of the hop matter etc as you can.

6. Add fresh cool water and stir in extracts to reach 17 litres, checking temperature.

7. Add warm or cool water to hit 19 litres at 12°C.

8. Oxygenate or aerate and inoculate with yeast.

9. When FG stabilises, keg or bottle as usual.

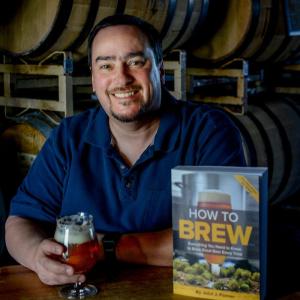

John Palmer is the author of the bestselling home brew book How to Brew. In every issue of Beer & Brewer magazine he does a deep dive into a particular facet of brewing better beer and regularly provides one of his recipes. Subscribe to our magazine here.