It’s been 10 years since the Krones Group’s brewing technology expert Steinecker launched the EquiTherm energy recovery system. It’s now used worldwide to sustainably produce roughly 65 million hectolitres of beer per year.

The system’s huge popularity should be no surprise, as by recovering surplus energy from the hot wort, the demand for primary energy is eliminated during the mashing process. This reduces the amount of energy required and improves the CO2 footprint in the brewing process. As a result, thermal energy and electrical energy consumption in the brewhouse can be cut by up to 55 per cent and 40 per cent respectively.

Breweries can also integrate the EquiTherm system into their existing brewhouses irrespective of whether the brewing equipment was supplied by Steinecker or not. However, a certain amount of effort is required for this as the necessary activities often include replacing sections that are not capable of operating such a highly efficient recuperation system.

New Steinecker brewhouses ready for EquiTherm as standard

The retrofitting of EquiTherm is much easier. Since all new Steinecker brewhouses from 2022 come ready equipped for the EquiTherm system, meaning it should be relatively easy to retrofit them without having to actively select this option.

Mash tun kettles, for example, will also be fitted with energy-recycling hot water heating surfaces at the bottom as standard, although they do not necessarily have to be operated with hot water from the start. However, they will be able to deliver the necessary efficiency to work with recovered low-temperature hot water instead of steam as the heating medium sometime in the future. Other plant components have also been designed for use with the energy recovery system. Basically, EquiTherm paves the way to low-temperature brewing and thus to the Steinecker Brewnomic concept, which aims for climate neutrality.

CombiCube also equipped accordingly

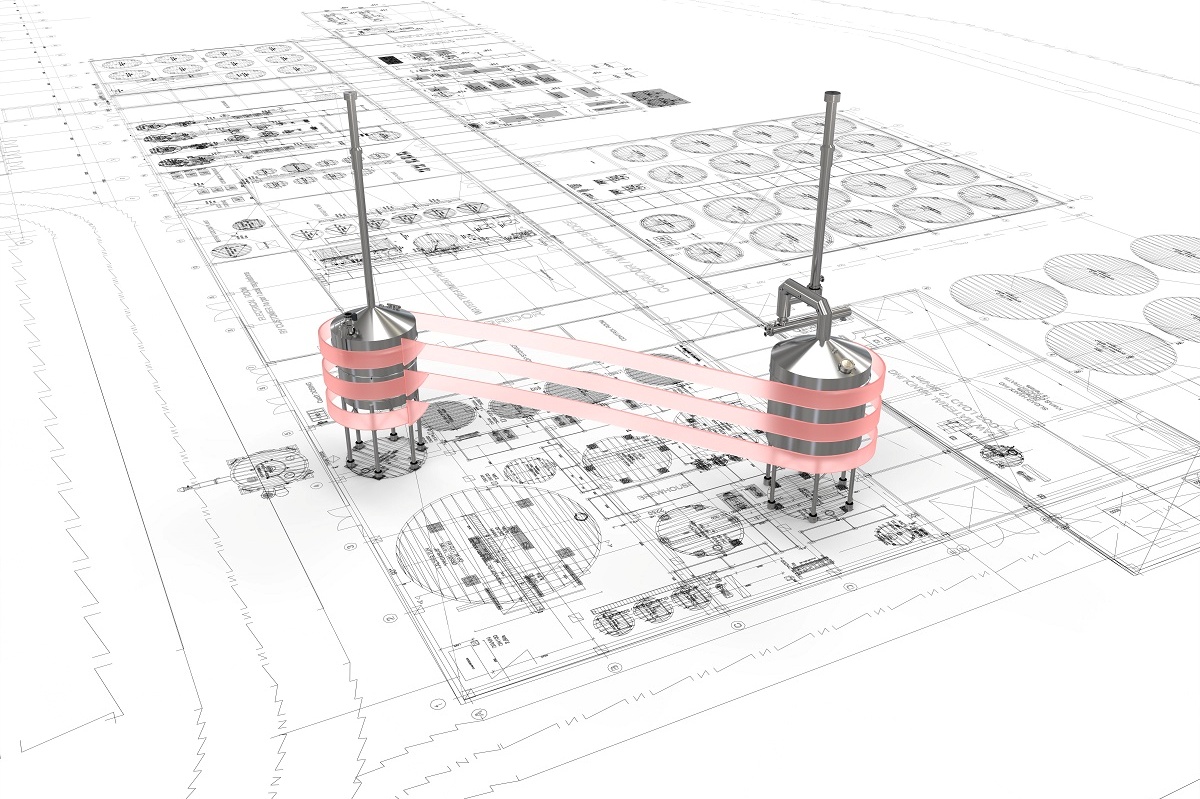

All new breweries featuring Steinecker equipment from 2022 will come with this new standard – so not only those that opt for a conventional brewhouse with brew sizes above 130 hectolitres, but also all those that produce smaller volumes and therefore rely on the CombiCube compact system. The modular brewery concept is suitable for cold wort volumes of 25 to 130 hectolitres per brew and is ideally suited to the needs of craft brewers and microbreweries – since sustainability also plays a key role for this target group during the brewing process.

Read more about the EquiTherm energy recovery system here.

This is a sponsored content piece. To find out more talk to the Beer & Brewer sales manager.