Red IPAs were born from the dark ages of craft beer, when microbrewery styles consisted of pale, amber and dark.

American amber was the precursor to red IPA and these beers relied heavily on caramel malts for flavour (because they were often the only specialty malt in town), and Cascade hops.

The bitterness to gravity ratio (BU:OG) for amber ale was typically at 1:2. The IPAs of the day were a bit higher at 3:4 but the IPA revolution, with a 1:1 ratio, was still a decade away.

American amber ale was, and is, a delicious beer with 15 – 25% caramel malts in the grain bill. Amber ale was big and hearty, which was a stark contrast to the ubiquitous American light lagers.

It was only a matter of time before amber and IPA recipes converged to create the red IPA. The copious caramel malt flavours had plenty of room for more hops and bitterness but there was an Achilles heel lurking in wait for the gleeful brewer, one that mostly succeeded in killing the style just as it was reaching maturity. And that flaw was hop flavour.

What?! How can that be? Well, it’s a question of balance and harmony. Americans tend to overhop everything, and in the case of the red IPA, we muddied the balance between the malt and hop character. The original amber ales were malty with a balancing bitterness and an extra dose of hop flavour and aroma to add complexity to what would have otherwise been just another malty sweet British beer.

Red IPA added bitterness and dry hopping, which added more balance and accent to the predominately malt flavours and aromas of the style. And then whirlpool hopping and all late-hopping entered the game and ruined it.

Too much hop flavour on top of caramel and melanoidin malt flavours generally creates a mess.

THE SECRETS TO A PROPER ONE

Red IPA is all about old school techniques – big bitterness charge, a bit of late hopping during the boil for some flavour, followed by dry hopping. The typical old school dry hopping rate was one pound per barrel, which is about 4 grams per litre.

The BU:OG balance of a red IPA should be 1:1 and the overall hop profile should be 50% of your hop bitterness at 60 minutes, 25% at 30 minutes, 25% in the last 15 minutes of the boil, followed by a 4 grams per litre level dry-hopping.

The dry hopping of the day imitated the British cellaring of cask ales – the hops would be added to the fermenter at cool temperatures (12 – 16°C) and left for a week before racking and bottling. Yes, this is not much hop flavour and aroma compared to today’s hazy IPAs and that’s because it is a different style with its own balance.

A well-crafted red IPA has good clarity with very little haze. It should be a deep amber with red highlights (not orange). The foam should be ivory or creamy in colour and thick and long lasting. The beer’s aroma should be hoppy and clean with citrus and piney notes, but interlaced with a strong caramel and bread crust malt character. The ester character is generally restrained, depending on the use of American or English ale yeast strains. The flavour of a red IPA should be balanced – generally the hop bitterness will dominate the upfront flavour, but the malt flavour supports the middle and finish, tapering off to a dry finish. The bitterness should not linger on the palate. Lingering bitterness is a sign of not enough sulphate in the brewing water.

WATER PROFILE

Red malts are the most acidic (followed by brown, then black, then amber) because the acidity of specialty malts increases with malt colour, up to about 120 Lovibond (240 EBC). This is a deep red colour, and then the acidic compounds begin burning and degrading as the malt darkens to brown and black. Malt acidity is covered in more detail in my book Water.

For red IPA, the water profile should be something like 75 ppm calcium, 20 ppm magnesium, 50 ppm bicarbonate, 200 ppm sulphate, 50 ppm chloride and 25 ppm sodium with a residual alkalinity near zero, which, with these numbers, works out to about (-)5.

The thinking here is that 75 ppm is a good calcium level for beer clarity and medium mineral structure, 20 magnesium is good for yeast health, 200 sulphate is good for a clean crisp hop character, the chloride and sodium are low but slightly enhance the malt character and the near zero residual alkalinity value along with the caramel malt bill will drive the mash pH down to about 5.4, which will be good for a clean hop expression and malt brightness.

This water profile can be built using 20 litres of distilled or RO water, 4 grams of calcium sulphate, 2 grams of calcium chloride, 4 grams of magnesium sulphate and 2 grams of baking soda.

Closer to the Heart Red IPA All Grain Recipe

(expected figures)

OG: 1.061

FG: 1.016

ABV: 6.0%

IBU: 60

Volume: 20 litres

Ingredients

4kg Pale malt

1kg Crystal (60L) malt

100g Roasted Barley*

60g Centennial pellets

55g Amarillo pellets

80g Cascade pellets

2 packs US-05 Ale yeast

Method

- Heat 25.6L water to 71°C. You are shooting for a mash temperature of 67°C.

- Immerse the grain bag in the water and stir the grist to ensure it is fully wetted.

- Mash with occasional stirring for 1 hour.

- Lift the grain bag out of the kettle and allow to drain. You should have 23L of 1.054 wort.

- Once boiling, add 30g Centennial hops for a 60 minute boil.

- With 30 minutes left on the boil, add 25g Amarillo hops.

- With 15 minutes left on the boil, add 50g Cascade hops.

- At end of boil check volume and gravity, you may need to add water to hit 20L.

- Chill wort to 20°C and pitch yeast.

- Allow 2 weeks for fermentation and maturation until dry hopping in fermenter with 30g Centennial, 30g Amarillo, 30g Cascade hops in a hop bag.

- After 1 week, remove hop bag and bottle or keg as usual.

*Note: Substituting Simpsons Red Rye (100L) for the Caramel 60L makes a great Red Rye IPA.

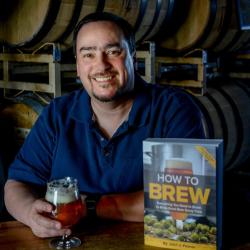

John Palmer is the author of the bestselling home brew book How to Brew. In every issue of Beer & Brewer magazine he does a deep dive into a particular facet of brewing better beer and regularly provides one of his recipes. Subscribe to our magazine here.