I’m sure everyone can think of a time or a place where the taste of beer would be very refreshing, but the presence of alcohol is a problem. Fortunately, there are some new options available to us these days that make these types of beers much more palatable than they used to be.

Before we discuss the brewing, let’s define a few terms first. In the United States, low alcohol is defined as less than 2.5% ABV, no alcohol as less than 0.5%, and alcohol free as less than 0.05%.

The oldest method for making low or no-alcohol beer was to heat it to near boiling, allowing the alcohol to vaporise away. One home brewing method is to place a kettle of beer in the oven at 80-85°C for half an hour, or you could use a sous-vide heater as well. There are several problems with these methods however, and all of them have to do with flavour.

Any high heat allows staling and oxidation reactions to speed up, resulting in a stale tasting and much darker beer. The other problem is that most of the hop character and fermentation character (esters) will have vaporised away as well. You could add more hops to the hot beer or dry hop to bring back some hop character, but the malt character will stay changed.

Of course, reducing the pressure on a liquid lowers its boiling point, and there are commercial systems that can reduce the boiling point of beer down to more reasonable temperatures, such as 50°C or lower. It’s better, but still very different from a non-heated beer.

Membrane filtrations & incomplete fermentations

Fortunately, there are two new ways to achieve low alcohol beer. Membrane filtration is the way that most commercial low or no alcohol beers are made today. You essentially run the beer into a reverse osmosis filtration and create dehydrated beer syrup. The alcohol comes out with the water and then they rehydrate the beer syrup with fresh, distilled, de-aerated water and you have reconstituted beer. But don’t try this at home! The reason is that the beer needs to be pre-filtered to remove the yeast and haze, otherwise it will clog the membrane. Putting a typical homebrew through a typical home RO system will clog it immediately. I am drinking one right now and I have to say it’s not bad. A bit watery, and not very complex in the ester profile – fruity with a lot of red apple, but it is definitely a light beer.

The other common way to make a low alcohol beer is to make a low gravity wort. If you brew a 1.030 gravity wort using high mash temperatures, such as 70-75°C, you will create a dextrinous wort with lower fermentability and can achieve 2.5% ABV or less with any standard ale or lager yeast. This is, quite frankly, the best way to make a low alcohol beer. It will taste like beer because it is beer. I will give you a good recipe shortly.

The game changer

The new player in this game are the new yeasts, such as Fermentis’ LA-01 and White Labs’ WLP 618. These yeasts do not ferment maltose or any of the higher sugars, they only ferment the simple sugars of glucose, fructose, and sucrose. They have an apparent attenuation of about 15% instead of the usual 70-80%. This equates to about 1% ABV for OG of 1.040-1.060. Raising the mashing temperature on these worts can reduce the fermentability further, and you may be able to achieve 0.5% ABV if that is your goal.

There is a caveat to these beers though, and that is that they are not microbiologically stable! Think about it – there is a lot of unfermented sugar in this beer, and low alcohol – there is nothing other than the hops to inhibit a wild yeast or bacteria from contaminating the brew and causing bottle bombs; so be careful with your sanitation! It would probably be best to keg and force carbonate this type of beer to avoid the chance of bursting bottles. However, these new yeasts do provide a means to make a bigger, fuller tasting low alcohol beer.

Here are two points to keep firmly in mind if you are going to use a non-attenuating yeast:

- You are used to drinking beers with a final gravity in the 1.005-1.015 range; anything higher is going to seem too heavy and too sweet, so bring your original gravity down appropriately.

- Low alcohol is going to mean that the beer is not microbiologically stable. These beers can spoil, just like old food in the refrigerator! For best results, keep the resulting beer cold and check the pH of the beer to be sure it is 4.6 or less. Acidify it if necessary, using common brewing acids such as lactic, citric or phosphoric.

Let’s talk recipes

To brew a low alcohol beer using normal beer yeast, plan for a starting gravity in the 1.025-1.035 range, which should give you a beer with 2-3% ABV. Plan your hopping accordingly with a 1:2 Bitterness to Gravity Unit ratio, such as 15 IBU for a 1.030 OG wort. You could go as high as 1:1 for a low alcohol West Coast IPA, also known as a Session IPA. Low gravity worts often lack body, so another thing you can do is crank up your mashing temperature to 70-72°C to minimise the fermentability while maximising the dextrins. The combination of low gravity wort with high mashing temperature and a normal beer yeast should get you into the 1-2% ABV range.

Next, if you want to really bring the alcohol down, you can use one of the low alcohol yeasts, but as I stated above, you have to be aware that low alcohol and no alcohol beer is not shelf stable. A low alcohol beer made with normal beer yeast is more shelf stable because all of the fermentable sugars have been consumed. With low attenuating (ie. maltose-negative) yeast, there is a lot more food for wild yeast and bacteria to eat if they can get in. So check the pH at the end of fermentation, and acidify it if it’s greater than 4.6. You can prime and bottle with these maltose-negative yeasts just like with normal yeast, but be very careful with your sanitation! If you have any wild or normal beer yeast hanging out in your bottling bucket or siphon, there is a chance that it can get into your bottles and over-carbonate them.

Brew day

When brewing this beer, it is vital to hit the high mash temperature, and if you are able to manipulate your brewing water then do so. I recommend the following:

| Ca | Mg | Total Alk | SO4 | Cl | RA |

| 75-100 | 10-20 | 50-100 | 100-150 | 100-150 | 50-75 |

All grain recipe: Lowbrow Dark Ale

(expected figures)

OG: 1.030

FG: 1.012

ABV: 2.4%

IBU: 15

Volume: 19 litres

Ingredients

2kg Pale malt

350g Munich malt (10L)

100g Crystal malt (60L)

100g Roasted Barley (500L)

25g Fuggles hop pellets

20g Goldings hop pellets

Mangrove Jacks M44 WC Ale yeast; or Fermentis LA-01 yeast; or White Labs WLP 618 (make sure to read notes on yeast selection in main article)

Method

- Heat 24 litres of water to 75°C and immerse the cracked grains inside the grain bag (nylon mesh bag or similar). Mash for 60 minutes, stirring occasionally aiming for 70°C mash temp.

- After the hour, lift the bag out and allow to drain. You should be left with about 22 litres of wort at 1.025 gravity.

- Bring to the boil, then add the Fuggles hops for a 30 minute boil.

- At the end of the 30 minute boil, turn off the heat and add the Goldings hops for 15 minutes to steep.

- Chill your wort to pitching temperature (20°C) and transfer to your fermenter, where you should have 20 litres of 1.030 wort.

- Pitch your yeast and allow at least a week to ferment. Check for constant terminal gravity over two days, and pH before bottling or kegging.

- Bottle or keg as normal then enjoy!

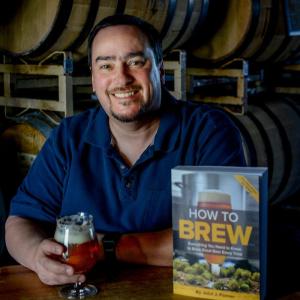

John Palmer is the author of the bestselling home brew book How to Brew. In every issue of Beer & Brewer magazine he does a deep dive into a particular facet of brewing better beer and regularly provides recipes. Subscribe to our magazine here.